Illustrate

1)min flow:0.5ml/min

2)Siemens CNC machining center

3)2 national patent technology

4)More 30 years’ technology accumulation

5)9 consecutive years as gold supplier for export

Micro oval gear flow meter provide precise volumetric flow measurement of clean liquids found in a broad range of industries including automotive, aviation, mining, power,paint & petroleum. Applications include the distribution of fuels, fuel oils, lubricants, alcohols, blending of bio & ethanol fuels, grease, adhesives, ink, insecticides & non-conductive liquids either pumped or gravity fed

Why Choose Us?

Engineers’ team is from Siemens

Siemens CNC machining center

2 national patent technology

More 30 years’ technology accumulation

9 consecutive years as gold supplier for export

Accuracy is higher 40% than counterparts

Range ration is 3~5 times than counterparts

ISO,CE,SGS certificate

Max pulse ratio : 40000 P/L

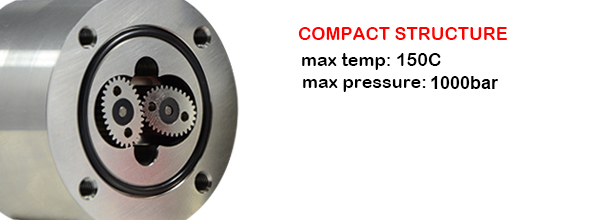

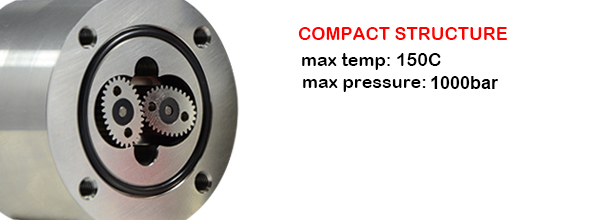

Max working pressure: 1000bar

Gear and shaft can be changed by yourself

Mainly using conditions for Micro Oval Gear Flow Meter

|

hydraulic system |

precision dosing |

2 and 3 component application |

|

process control |

open/closed loop control |

corrosive chemical dispensing |

|

water treatment |

additive injection |

automobile industry |

|

system monitoring |

laundry chemical |

plastic technology |

|

print process |

chemical batching |

chemical packaging and blending |

|

ratio control |

consumption measurement |

oil metering |

|

metering plant |

hydraulic test stand |

batching control |

|

lacquering plant |

2 component plant |

flow rate measurement |

|

dosing |

Odorisation |

closed-loop management |

Mainly medium for Micro Oval Gear Flow Meter

|

water |

gum |

chemicals |

fluid |

|

oil |

dyes |

liquid |

adbrasive adhesive |

|

grease |

petrochemicals |

isocyanate |

two-component mixers |

|

paints |

adhesive |

ink |

waterbased liquid |

|

skydrol |

brake fluid |

hydraulic oil |

sealant |

|

gear oil |

low viscosity |

lubracating |

methylbenzene |

|

Diesel |

Methanol |

methyl alcohol |

medium viscosity |

|

polyol |

high viscosity |

offset ink |

Toluene |

|

lacquer |

low lubricity |

resin |

Pharmaceuticals |

|

solvent |

cavity wax |

wax |

clear lacquer |

|

glycol |

glycerin |

sodium hydroxide |

caustic soda |

|

ethylene |

diethylene |

triethylene |

propylene |

|

corn oil |

cocoanut oil |

molasses |

bhylene |

|

palm oil |

olive oil |

lard oil |

cotton oil |

|

soy bean oil |

rosin oil |

rape seed oil |

dimethylthylsufid DMS |

|

additive |

syrup |

sugar |

electrohydrodynamic |

|

liquefied gas |

perfume |

aromatic substance |

pharmaceutical |

|

peanut oil |

fluid food |

thioether |

tetrahydrothiophen THT |

|

acryiat-composite |

Thiol |

mercaptan |

mercaptan-composite |

Basic Parameters

|

Accuracy |

0.5% or 0.3%, |

|

Temperature |

-30~80°C(customized) |

|

Pressure |

32bar(customized) |

|

Output |

square-wave pulse |

|

Supply |

4-26VDC |

|

Material |

chamber:SS316L or anodized aluminum |

|

Model |

Flow range |

Connection |

|

AK-M2-SS/AL |

0.5~150 ml/min |

G1/8 female thread |

|

AK-M3-SS/AL |

1-300 ml/min |

G1/8 female thread |

|

AK-M5-SS/AL |

5-1000 ml/min |

G1/8 female thread |

|

AK-M6-SS/AL |

0.5-100 l/H |

G1/4 female thread |

|

AK-M9-SS/AL |

5-550 l/H |

G1/4 female thread |

|

AK-M12-SS/AL |

1~30 L/min |

G1/2 female thread |

|

AK-M25-SS/AL |

5-110 l/min |

G1 female thread |

|

AK-M40-SS/AL |

10-250L/min |

G1 1/2 female thread |

|

AK-M50-SS/AL |

10-500L/min |

G2 female thread |